About

Services

Experience

Projects

Contact Us

Blades

Design Group LLC

Automation

A solar cell metalization line using commercially available silk screening machines was a project for us in 2002. The contract was for design of the entire system, including mechanical design, controls and machine control software. On-site guidance during assembly was also required. Two lines were being built using two different types of drying ovens. NFPA and CE compliance were also requirements.

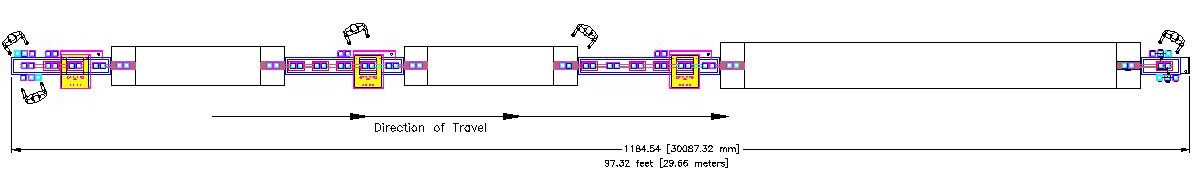

The line takes partially processed cells from a stack and first screens conductive ink on the rear side. Next the ink is dried in a belt oven and then a second coat, using a different pattern of conductive ink, is screened on the rear side. After a second drying oven, the cells are flipped to the front side and a final screening process applies conductive ink to the front side. All of the ink coatings are then fired in a firing oven. At the end of the line, the cells are re-stacked. The cell loading and unloading systems are designed to switch between two positions, allowing continuous operation.

The line consisted of four electro-mechanical sections and a control console. The control console contained a PC to control the line and power distribution components. Control of the equipment was accomplished over an ethernet network between the control console and the four sections.

The mechanical and electromechanical portion of the machine were designed in AutoCAD®. The control software is a proprietary application running on WINDOWS 2000®.

Plan View Layout

A solar cell metalization line using commercially available silk screening machines was a project for us in 2002. The contract was for design of the entire system, including mechanical design, controls and machine control software. On-site guidance during assembly was also required. Two lines were being built using two different types of drying ovens. NFPA and CE compliance were also requirements.

The line takes partially processed cells from a stack and first screens conductive ink on the rear side. Next the ink is dried in a belt oven and then a second coat, using a different pattern of conductive ink, is screened on the rear side. After a second drying oven, the cells are flipped to the front side and a final screening process applies conductive ink to the front side. All of the ink coatings are then fired in a firing oven. At the end of the line, the cells are re-stacked. The cell loading and unloading systems are designed to switch between two positions, allowing continuous operation.

The line consisted of four electro-mechanical sections and a control console. The control console contained a PC to control the line and power distribution components. Control of the equipment was accomplished over an ethernet network between the control console and the four sections.

The mechanical and electromechanical portion of the machine were designed in AutoCAD®. The control software is a proprietary application running on WINDOWS 2000®.

Plan View Layout

CAD Drawings

of Sections

| Section 1 | Section 2 | Section 3 | Section 4 |

Copyright 2003 Blades Design

Group LLC